-

06-24 2025

Ultra-High-Molecular-Weight Polyethylene Sheet: Revolutionizing Industrial Applications

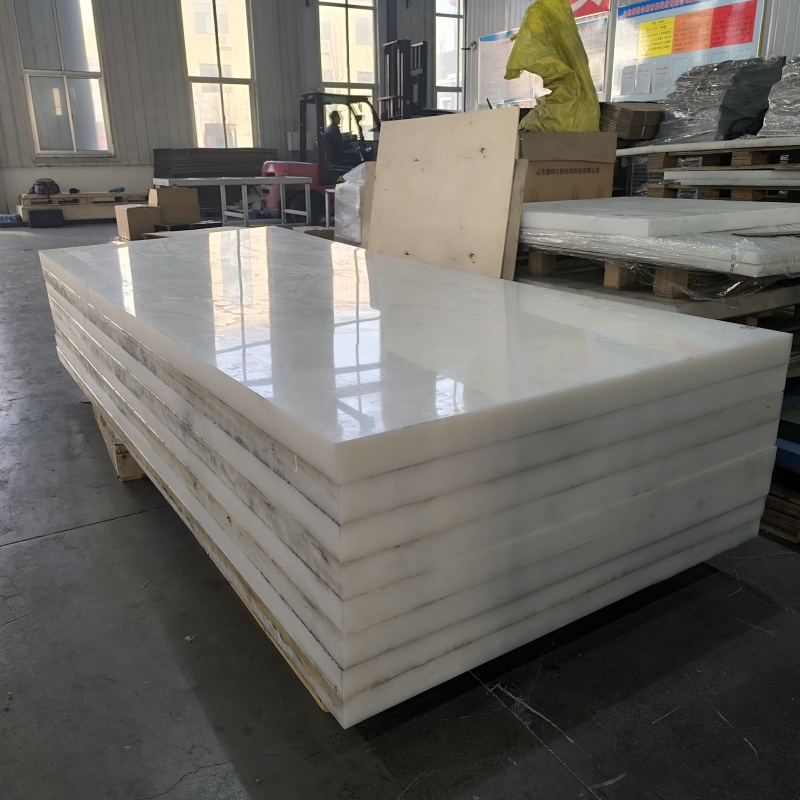

Shipment Of UHMWPE sheet to Southeast Asia Size:1500*3000*15mm Uhmwpe sheet shipped to Southeast Asia this week. This batch of UHMWPE sheets covers thicknesses from 5 mm to 50 mm, widths from 1.2 m to 2.2 m, and lengths can be customized up to 6 meters. The sheets are highly wear-resistant, impact-resistant and self-lubricating, and can maintain stable performance in complex industrial environments. It is understood that UHMWPE sheet is widely used in mining, chemical, machinery manufacturing and other industries in Southeast Asia can play an important role, can effectively improve the efficiency of equipment operation and reduce maintenance costs.

-

05-27 2025

HDPE Sheet Shipment to the USA

Shipment Of UHMWPE sheet to Southeast Asia Size:1500*3000*15mm Uhmwpe sheet shipped to Southeast Asia this week. This batch of UHMWPE sheets covers thicknesses from 5 mm to 50 mm, widths from 1.2 m to 2.2 m, and lengths can be customized up to 6 meters. The sheets are highly wear-resistant, impact-resistant and self-lubricating, and can maintain stable performance in complex industrial environments. It is understood that UHMWPE sheet is widely used in mining, chemical, machinery manufacturing and other industries in Southeast Asia can play an important role, can effectively improve the efficiency of equipment operation and reduce maintenance costs.

-

04-25 2025

What are the characteristics of UHMWPE?

-

04-21 2025

How to avoid UHMWPE sheet off the warehouse?

-

04-17 2025

Flame retardant antistatic paving mat In the coal mine production process

Flame retardant antistatic paving mat In the coal mine production process In the coal mine production process, equipment operation, material transportation and personnel activities will generate static electricity. If the static electricity cannot be removed in time, it may trigger sparks, which may lead to serious accidents such as gas explosions. Flame retardant antistatic paving slabs have good electrical conductivity on the surface, which can quickly conduct away the static electricity generated, avoiding the safety hazards brought about by static electricity accumulation. In the complex and changing environment of underground coal mine, paving materials need to withstand the frequent passage of heavy machinery and equipment and vehicles, as well as the erosion of mine water, acid and alkali substances. Flame-retardant antistatic paving mats are made of high-strength, wear-resistant and corrosion-resistant materials, which can keep flat and stable for a long time and prolong the service life. Flame retardant antistatic paving matting is made of lightweight material, which is easy to handle and install. At the same time, it has enough strength and load-bearing capacity to withstand the weight of heavy machinery and equipment and vehicles to ensure the safety and stability of mine roads.

-

04-15 2025

How can you pick the excellent UHMWPE sheets?

How can you pick the excellent UHMWPE sheets? The molecular weight of ultra-high molecular weight polyethylene sheet is more than 3 million, which has the properties of wear-resistant, impact-resistant, chemical corrosion-resistant, self-lubrication, small wear coefficient, light weight, energy absorption, aging-resistant, flame-retardant and anti-static. UHMWPE sheet has a wide range of applications, UPE sheet can be used in textile machinery, papermaking machinery, packaging machinery, general machinery, material storage and transportation, agriculture, construction machinery, sporting goods, food, beverage industry, medical treatment, etc. UHMWPE sheet performance: 1、 UHMWPE board is very high wear resistance, due to its unique molecular structure, wear resistance is higher than all metal plastic products, carbon steel 6.6 times, stainless steel 5.5 times, brass 27.3 times, nylon 6 times, PTFE 5 times. 2、Good self-lubricating coefficient, small friction coefficient, small flow resistance, energy saving. 3、High impact strength, good toughness, even at low temperatures by the strong impact will not break. 4、excellent chemical corrosion resistance, can withstand (in addition to concentrated sulfuric acid, concentrated nitric acid, a few organic solvents) almost all acids, alkalis, salt media. 5、 UHMWPE sheet is non-toxic, odourless, no exudate. 6、 good resistance to electricity, very low water absorption rate. 7,、excellent resistance to environmental stress cracking performance, is 200 times the ordinary polyethylene. 8、excellent low-temperature resistance, even at -180 ° C does not fracture.