-

04-09 2025

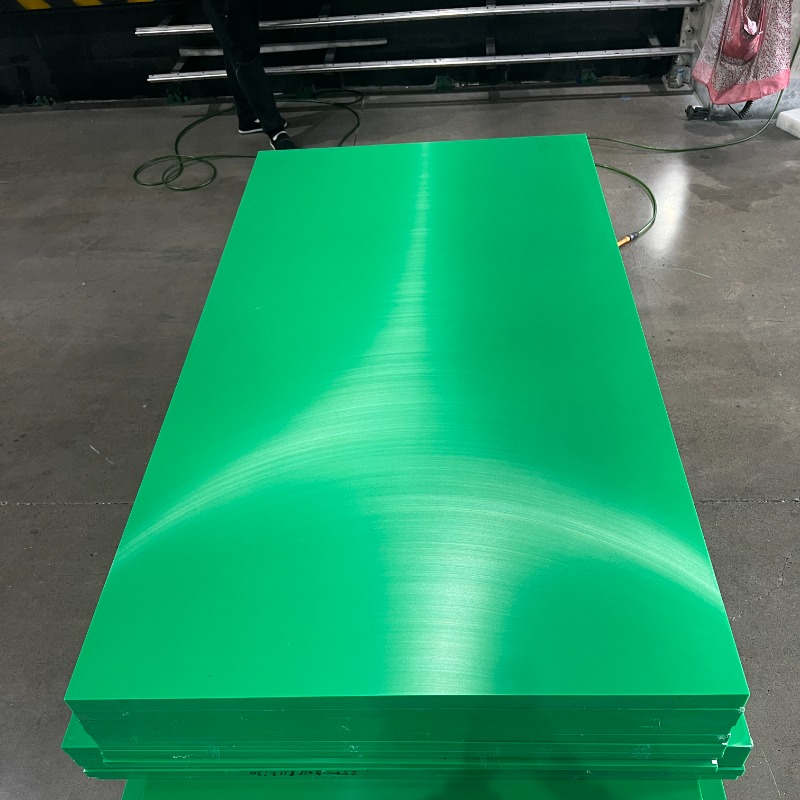

UHMWPE liner plate

UHMWPE liner plate UHMWPE liner plate is a kind of high performance engineering plastic liner plate with excellent wear resistance, impact resistance, self-lubrication, low temperature resistance and chemical stability. The molecular weight of UHMWPE liner plate is very high, which can reach 1-4 million, which makes its performance of wear resistance, impact resistance and self-lubrication have been significantly improved. This kind of liner can be used as the lining material of conveyor, which can play the role of wear-resisting, impact-resisting, reducing the adhesion of materials and lowering the noise during the conveying process. The low temperature resistance of UHMWPE liner is also very good, even at very low temperatures, its strength and stiffness will not be significantly reduced, for example, in some northern Europe or alpine areas, it can be used as the liner material for bulk material conveyor. In addition, UHMWPE liner has excellent chemical stability. It can be stable in a variety of chemical environments, will not be corroded or deteriorated, for example, in the chemical industry, pharmaceuticals, food and other fields of the material conveying process, can be used as a lining material. Finally, UHMWPE liner board also has excellent processing performance. It can be easily cut, drilled, bent and other processing operations, and there will be no obvious deformation or cracks. This allows it to be customised to meet a variety of different application scenarios. In conclusion, UHMWPE liner board is an excellent engineering plastic liner board, and its advantages of high performance, high molecular weight and excellent processing performance make it can be widely used in various fields.

-

04-07 2025

What is ultra-high molecular weight polyethylene sheet?

What is ultra-high molecular weight polyethylene sheet? Ultra High Wear Resistance Ultra High Molecular Weight Polyethylene Sheet, referred to as UHMWPE sheet, is a high-quality engineering plastic sheet. It is made of ultra-high molecular weight polyethylene as raw material and processed through a special production process. With extremely high wear resistance, corrosion resistance, impact resistance and self-lubrication. UHMWPE sheet is one of the hottest engineering plastic sheets on the market. The abrasion resistance of UHMWPE sheet is one of the most prominent features, and its abrasion resistance is more than 5 times higher than that of ordinary polyethylene. In the environment of high load and high speed operation, the wear resistance of UHMWPE sheet shows more excellent performance, which can effectively extend the service life of machines and equipment and reduce the maintenance cost. The corrosion resistance of UHMWPE board is also excellent, it can withstand acid, alkali, salt and other chemicals, and will not be ruptured or aged due to chemical reaction. At the same time, UHMWPE board also has good impact resistance, can effectively resist a variety of impact and vibration, in a variety of harsh environments can maintain outstanding performance. In addition, UHMWPE board has self-lubricating property, which reduces the friction with other materials, makes the material smoother and prolongs the service life. To sum up, UHMWPE sheet is a high-quality engineering plastic sheet, which is widely used in chemical, electronics, food, packaging, printing, textile and other industries.

-

04-03 2025

Production process of UHMWPE outrigger plate

Production process of UHMWPE outrigger plate The production of UHMWPE outrigger plate usually adopts compression molding process. The basic steps of the process include: 1. Preparation of raw materials: Polyethylene granules of very high purity are selected to ensure the quality of the final product. 2. Mixing and molding: The polyethylene granules are mixed evenly with the additives and then placed into the mold for high temperature and high pressure molding. Due to the high molecular weight of UHMWPE, special equipment and techniques are usually required to ensure that the material fills the mold evenly. 3. Cooling and Removal: The molded mat is cooled and removed from the mold, followed by post-processing. The post-processing may include grinding, trimming, etc. to ensure dimensional accuracy and surface smoothness. 4. Inspection and Packaging: The completed mat boards are subject to strict testing to ensure that their performance indicators meet the relevant standards, and then packaged and ready for shipment.

-

03-28 2025

Advantages and application areas of UHMWPE liner

Advantages and application areas of UHMWPE liner Advantages of UHMWPE liner: 1. high wear resistance and low coefficient of friction, to prevent material flow obstruction; 2. non-absorbent, not affected by the humidity of the material; 3. very low coefficient of friction, so that the adhesion is large, not easy to free flow of bulk material flow smoothly; 4. protection of the equipment, not corroded by the material caused by equipment failures; 5. lightweight, only 1/8 of the steel, easy to repair and replacement. UHMWPE lining application areas: Widely used in the mining industry, coal processing plants, metallurgical industry, thermal power plants, shipbuilding industry and other sectors of the transportation of liquids, solids, solid-liquid mixtures of funnels, funnels, tipping boards, scraper conveyor skid, jigger screen plate, flotation machine liner, ship cargo hold liner, large skid, mining trucks, tipper carriages lining, etc. Wear-resistant corrosion-resistant applications, with the unique advantage of value for money.

-

04-01 2025

Application areas of UHMWPE outrigger plate

Application areas of UHMWPE outrigger plate 1. Mining and heavy machinery: In mining, dock and other heavy-duty operations, UHMWPE outrigger plates can effectively carry heavy loads and reduce equipment damage and maintenance costs. 2. Aerospace and aviation: Because of its superior wear and impact resistance, UHMWPE outrigger plates are also used in part of the structure of the space shuttle and aircraft support components. 3. chemical and pharmaceutical industry: due to its excellent chemical stability, UHMWPE is widely used in chemical pipelines, tanks and pharmaceutical equipment. 4. construction and engineering: in construction, UHMWPE outrigger plates are commonly used in load-bearing structures and vibration-damping facilities, which can improve the safety and stability of the building. 5. Transportation and logistics: In logistics management, UHMWPE outrigger plates are used in forklifts, lifts and storage equipment to provide support and ensure the smooth progress of transportation.

-

03-25 2025

Flame retardant antistatic paving mat

Flame retardant antistatic paving mat Flame retardant antistatic paving mat is a kind of paving material specially designed for the harsh environment such as underground coal mine, with multiple properties such as flame retardant, antistatic, wear-resistant, corrosion-resistant, etc., which is very suitable to be used as temporary paving material for underground coal mine. Flame retardant and antistatic paving matting is added with flame retardant and antistatic materials during the manufacturing process. Polyethylene itself has excellent chemical stability and impact resistance. By adding flame retardant and antistatic materials, the paving mat has flame retardant and antistatic properties while maintaining its original mechanical properties. The flame retardant and antistatic paving mat adopts special flame retardant material and process, which can effectively reduce the flammability of the material and reduce the probability of fire. Once encountering an open fire or high temperature heat source, it can quickly form a carbonized layer, effectively isolating oxygen and preventing the fire from spreading. At the same time, the amount of toxic gases released during the combustion process is very small, posing no threat to the lives of miners. This characteristic is especially important in the flammable and explosive environment such as underground coal mines.